PCB, -Hole, -Grid, sheet thickness

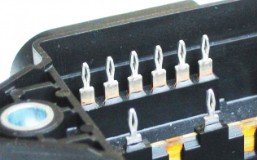

BIZON contacts:- many suitable materials with any sheet thicknesses.

- preferably square cross-section.

- can be adapted to existing hole diameters.

- allow a small pitch. Good for miniaturization.

- higher dielectric strength. Due to the system small holes result in a larger hole spacing.

Important for 48 volts and higher.Dimensions for BIZON contact sizes and PCB holes

Standard Sheet thickness 4) mm | Pin-dimensions 1) mm | smallest stamping pitch mm 2) | Standard finished hole- LP 4) mm |

0,2 | 0,2 x 0,24 | 0,81 | 0,34 ±0,04 |

0,4 | 0,4 x 0,5 | 1,2 | 0,60 ±0,05 |

0,51 | 0,51 x 0,62 | 1,3 | 0,85 ±0,05 |

| 0,6 | 0,6 x 0,6 | 1,3 | 0,85 ±0,05 |

| 0,63 | 0,63 x 0,64 | 1,3 | 0,85 ±0,05 |

0,60 3) | 0,60 x 0,85 | 1,45 | 1,0 ±0,05 |

0,63 3) | 0,63 x 0,83 | 1,45 | 1,0 ±0,05 |

| 0,8 | 0,8 x 0,85 | 1,6 | 1,10 ±0,05 |

0,8 3) | 0,8 x 1,2 | 2,0 | 1,50 ±0,05 |

1,0 | 1,0 x 1,2 | 2,0 | 1,55 ±0,05 |

| 1,2 | 1,2 x 1,2 | 2,0 | 1,60 ±0,05 |

1,2 3) | 1,2 x 1,5 | 2,7 | 2,0 ±0,05 |

| 1,5 | 1,5 x 1,5 | 3,0 | 2,0 ±0,05 |

| 2,0 | 2,0 x 2,0 | 4,0 | 2,7 ±0,05 |

1) Punching dimension in the non-expanded area (neck) of the contact. 2) Only contact procedure 2. PCB hole spacing usually needs to be larger between separated potentials. 3) The contact is adapted to historically common hole diameters. 4) The contact size, sheet thickness and hole diameter can be freely selected according to the priority. | |||

Deviating maximum and minimum dimensions of the finished hole must be agreed with the contact manufacturer. The tolerance range (symmetrical, asymmetrical) is to be determined between the user and the manufacturer, taking all aspects into account.

BIZON contacts have the greatest force in the center of the contact. Therefore, the contact should be pressed in up to the center of the PCB thickness +0.2 mm. This is because it is most stable there.

Thinner PCBs, e.g. 1 mm or 0.8 mm, can also be used for these reasons.

For thicker PCBs, such as 2.4 mm or thicker, the center of the press-fit zone should be at least 0.8 mm from the bottom or top surface.

The press-fit tolerance in depth increases accordingly.

Restring width

In addition to the electrical connection, the restring should also mechanically secure the sleeve against displacement. Like a rivet head, for example.

Historically, there were press-fit contacts that generated very high displacement forces, so a wider rest ring was often of no help. So it depends very much on the contact properties how much "rest ring" you need. This can also be seen from the various manufacturers' catalog specifications.

The BIZON contact, with its 4 defined contact radii, generates very low shear forces on the entire sleeve.

For the BIZON contact, therefore, the smallest residual ring width required for the electrical connection is sufficient.

The IEC 60352-5 standard specifies a residual ring width of 0.15 mm.