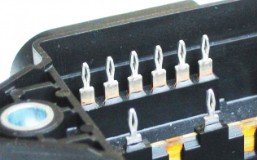

Eye of the needle

The needle

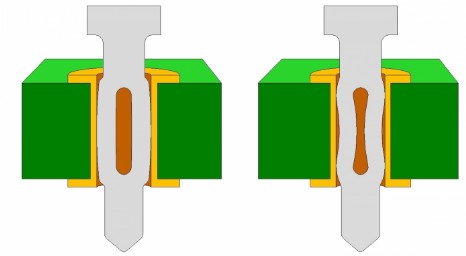

eye contact

eye contact

Mistake! Collapsed!

no contact

in the middle

in the middle

- Needle eye contacts (and similarly acting geometries) always have an inner distance between the two legs along their entire length.

- The hole must be larger by this distance. Loss of space.

- The clearance and creepage distance becomes smaller.

- The legs can actively jump inwards due to various faulty circumstances ("crackling frog", collapsing).

- Then no longer any contact in the middle (picture right), but only in the less stable edge area of the LP at the top (and perhaps at the bottom).

- For thinner printed circuit boards and especially for metallic punched grids (usually thinner than 1.6 mm), this behavior can lead to failure.

- Needle eye contacts for holes smaller than 0.6 mm can no longer be punched reliably (cracks).

The BIZON contact almost looks like an eye of the needle, but....

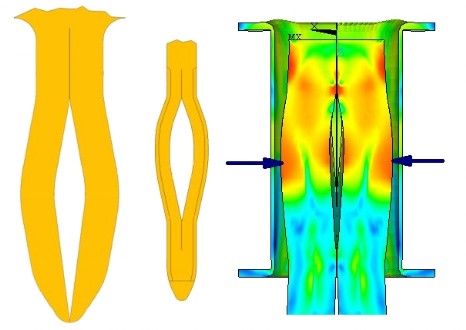

always greatest

contact force

middle of

printed circuit board,

there she is

most stable.

- BIZON contacts do not have any unnecessary distance between the legs, because they lie against each other at the top and bottom.

- The legs become more stable, more force, higher ampacity, full cross-section in the hole.

- Or the hole becomes smaller, thus smaller grid or higher dielectric strength also inside the printed circuit board (Caution 48 V, CAF).

- The contact force always remains in the contact centre.

- Therefore, thinner PCBs and press-fitting in punched grids (busbar, leadframe) are possible and safe.

- BIZON contacts are available for holes starting from 0.3 mm. There are no cracks on the legs, even with the strongest material.

- Jumping inwards (collapsing) is therefore impossible.