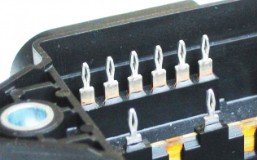

Surfaces on the BIZON contact and the printed circuit board

BIZON contacts can be bare or tinned. The tinning serves only as tarnish protection and must not be thicker than 1.2 µm. It is therefore only used for cosmetic purposes (brown copper parts do not look good). Other surfaces such as gold plating or silver plating are technically not necessary and rather unfavourable. A cold welding between contact and copper sleeve should be achieved.

Printed circuit boards can be HAL (hot air levelling), electroplated or chemically tinned. Or only organically passivated (OSP).

The BIZON contact penetrates the OSP layer without any problems, since it must even penetrate the copper sleeve.

With HAL tinning, there is a risk that the tin layer in the middle of the hole will be thicker. Due to the defined contact of the 4 edge radii of the BIZON contact, too much tin is pushed to the side and not out of the bore. Therefore there are no tin chips.

Gold-plated circuit boards should only be used together with press-fit technology if absolutely necessary for other reasons. Using gold plating only as corrosion protection is expensive and not a good idea.

As a diffusion barrier for the gold, the circuit board is first nickel-plated and then gold-plated. Nickel is much harder and more brittle than copper. Press-fit technology requires a deformation of the copper sleeve. However, this necessary deformation is usually too large for the nickel layer and it cracks. These cracks are points of attack for corrosion because three different metals are exposed.

A BIZON contact always has four contact points. Each of these contact points only has to bear 25% of the holding force. Therefore the deformation of the PCB can be small and there are significantly fewer and smaller cracks.

Whiskers

Due to its design, the BIZON contact pushes the tin layers at the contact points laterally into the free space, so that no permanent pressure can develop on the tin layer.

Basically, the BIZON contact does not need any tin at all (as lubricant). The minimum layer thickness would suffice as tarnish protection. Or only pre-tinned strip for optical reasons. Organic copper passivation (OSP) is another alternative.

Thus the BIZON contact offers a minimization of the whisker danger.

A low whisker coating of the printed circuit board and the BIZON contact itself is a prerequisite.

Years of observations have confirmed this.

If you have any questions write me a message here.